Modern data centers must be built faster, last longer, and operate with near-zero structural risk. Traditional steel reinforcement introduces corrosion exposure, maintenance uncertainty, and long-term lifecycle cost—especially in below-grade and moisture-exposed concrete.

Basalt Fiber Reinforced Polymer (BFRP) reinforcement offers a smarter path forward:

Corrosion-proof durability, lightweight installation, and long-term reliability engineered for mission-critical infrastructure.

Will not corrode in moisture, chlorides, or aggressive soils

Non-conductive and non-magnetic for electrically dense environments

Up to ~75% lighter than steel for faster placement and reduced labor

Lower lifecycle maintenance cost for long-term owners

Ideal for coastal, humid, and high-reliability sites

Even well-designed steel-reinforced concrete can deteriorate when exposed to:

Ground moisture

Chlorides in soil or deicing chemicals

Cooling tower drift and chemical exposure

Over time, corrosion leads to cracking, spalling, repairs, and operational disruption—all unacceptable in mission-critical data centers.

BFRP reinforcement does not corrode.

That single advantage can dramatically improve service life, reliability, and maintenance predictability.

Best-fit locations include:

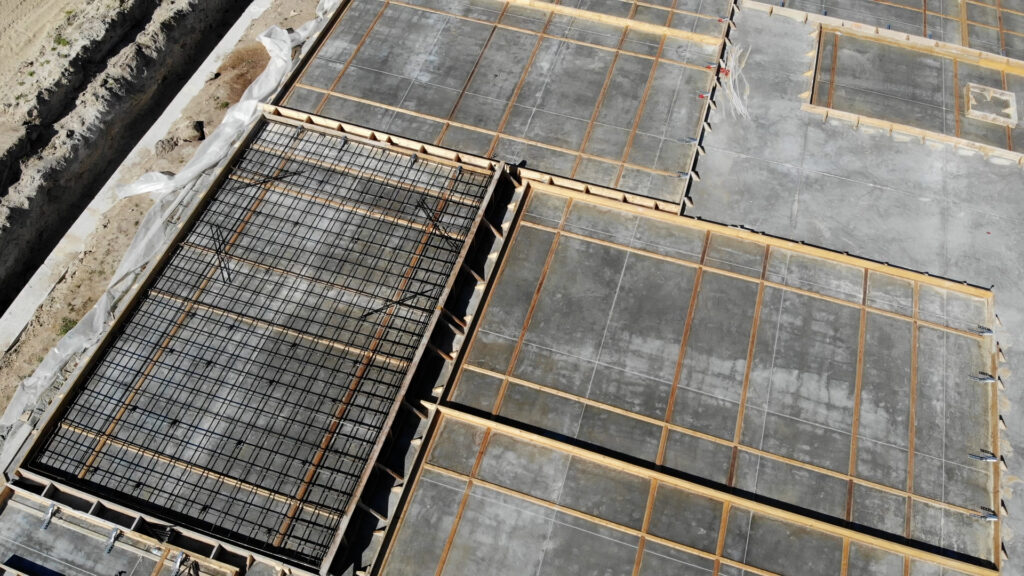

Foundations and grade beams

Slab-on-grade construction

Exterior generator and transformer pads

Cooling and utility structures

Steel reinforcement is conductive and magnetic—creating potential complexity around:

Grounding systems

Fault-current pathways

Sensitive electronic infrastructure

BFRP is non-conductive and non-magnetic, making it a natural fit for:

High-voltage equipment pads

Grounding-adjacent concrete

Fiber and communications infrastructure zones

For data centers, that means simpler design considerations and reduced electromagnetic concerns.

Data center economics are driven by speed to operation.

Every week saved means earlier revenue generation.

Because BFRP is significantly lighter than steel, crews benefit from:

Easier carrying and staging

Faster positioning and tying

Reduced fatigue during repetitive placement

Lower transportation weight

Result:

Faster reinforcement installation that helps keep critical construction schedules on track.

True sustainability in structural concrete comes from lasting longer and repairing less.

BFRP reinforcement contributes by:

Extending structural service life

Reducing repair-related material consumption

Lowering long-term embodied carbon

Supporting ESG and durability initiatives

For developers under sustainability pressure, durability is a powerful environmental advantage.

BFRP is especially valuable in concrete exposed to moisture, salts, or electrical sensitivity, including:

Foundations and mat slabs

Slab-on-grade systems

Generator and transformer pads

Cooling basins and containment

Underground utilities and duct banks

Perimeter site concrete

These are the locations where steel is most vulnerable—and BFRP performs best.

As digital infrastructure expands, owners are prioritizing durability, reliability, and lifecycle certainty alongside speed.

BFRP reinforcement delivers all three—providing corrosion-free performance, faster installation, and long-term structural confidence for mission-critical facilities.

Click Here to get support from the Basalt Engineering team on project-specific guidance, technical data, and specification support.