Lighter, stronger, non-corrosive, and environmentally sustainable. These are just some of the many attributes of BASTECH, a basalt fiber reinforced polymer (BFRP) that is part of the new wave of concrete reinforcement for public works, commercial, and residential construction. BASTECH BFRP bars, shapes and fibers can transform your project. See our products below and contact our reinforcement experts today to get started.

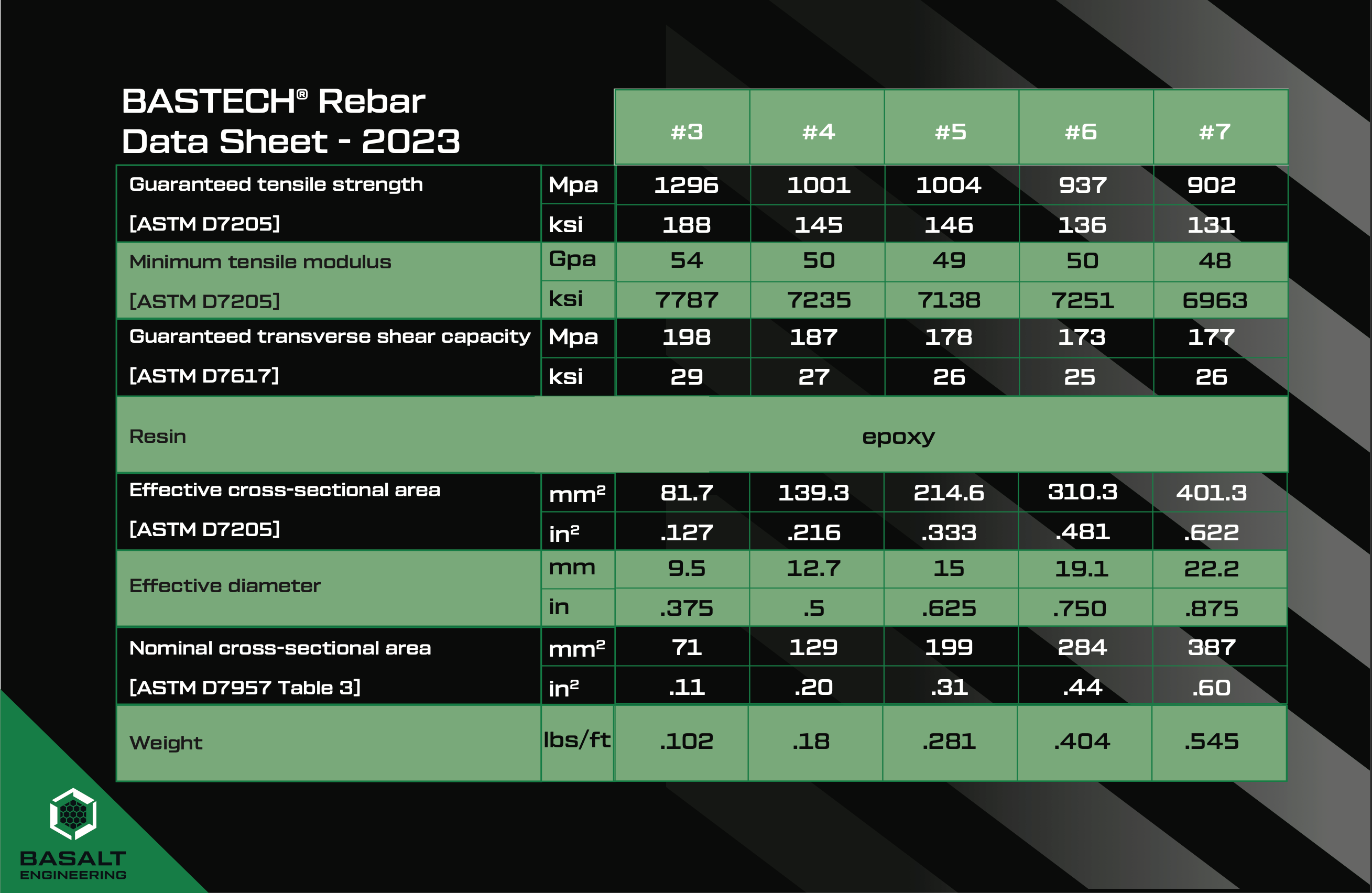

BASTECH Basalt rebar represents non-metallic concrete reinforcement rods of various lengths and standard diameters, which currently include #2, #3, #4, #5, #6, #7, #8 – bar size 1/4” (6mm) to 1” (25mm) diameter. Due to unique performance properties, it is an efficient and economical alternative to steel reinforcement. We can also manufacture custom diameters and lengths for customers with specific uses – for example, in manufacturing precast concrete products.

For large orders and tilt-up wall projects, we can manufacture rebar in custom diameters and lengths, and can kit it for quick installation.

Like our rebar and grid products, BASTECH Chopped Fiber exhibits the same benefits that make BFRP a concrete reinforcement material that is poised for growth in today’s environmentally conscious construction environment. Like BASTECH rebar and grids, our chopped fibers derive from basalt rock that has been melted and extruded into fibers. These thin fibers are chopped into short lengths to create BASTECH Chopped Fiber material that can be added to the concrete mix.

Our chopped fibers are relatively small, enabling them to disperse evenly throughout the concrete mixture. The high flexural and tensile strength of BFRP results in concrete structures with improved durability and crack resistance.

Unlike concrete reinforced with steel fibers, structures reinforced with BASTECH Chopped Fiber will not corrode. The light weight of the fibers simplifies handling and mixing and results in lighter concrete, which makes it advantageous for certain applications.

BASTECH Chopped Fiber is compatible with various types of concrete, including standard concrete, high- performance concrete and self-consolidating concrete. Chopped fibers can enhance many applications, such as pavements, bridges, tunnels, precast elements and other structures where BFRP’s enhanced mechanical properties are desired.

Upgrade your construction game with the strength of basalt chopped fiber. Order now and witness the transformation of your concrete structures into durable masterpieces!

Please Note: We require an order minimum of 1 metric ton.

Basalt Engineering works with our customers to provide custom shapes and bends using our state-of-the art manufacturing equipment. These shapes coordinate with our BASTECH straight rebar products to enable engineers, designers, and specifiers to design and build structures that meet reinforcement specifications for all types of applications and are particularly useful for precast concrete manufacturing.

FRP geogrids are typically produced through a process called extrusion or weaving. In extrusion, molten polymer material containing basalt fibers is forced through a die to create a continuous mesh structure with interconnected ribs and apertures. Alternatively, in weaving, basalt fibers are intertwined to form a grid pattern. Both methods result in geogrids with high tensile strength and durability suitable for various construction applications.

BFRP (Basalt Fiber Reinforced Polymer) geogrid mesh finds versatile applications in various construction projects. It is commonly used in soil stabilization and reinforcement applications for projects such as roadways, highways, embankments, retaining walls, and slopes. Additionally, BFRP geogrid mesh is utilized in reinforcing and strengthening concrete structures, such as bridge decks, parking lots, and airport runways, to enhance their durability and load-bearing capacity. Its high tensile strength, corrosion resistance, and lightweight properties make it suitable for a wide range of civil engineering applications.

Please Note: We require an order minimum of 35,000 square feet.

© 2025 All Rights Reserved. Basalt Engineering, LLC