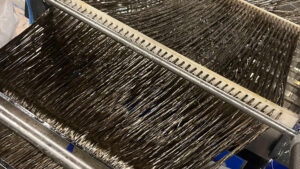

One of the most effective uses of basalt fiber reinforced polymer rebar is in the tilt-up construction sector. The enormous concrete panels manufactured on the construction site are poured, cured and lifted into place to construct all types of commercial buildings. Warehouses and data centers are particularly common in the tilt-up world, and ideal for BASTECH BFRP reinforcement.

As a lighter, stronger and non-corrosive to steel reinforcement, BASTECH rebar assembles easily and quickly onsite. At just 25% of the weight of steel and 2.5 times the tensile strength, BASTECH provides a host of benefits for both contractors and project owners. We recently completed a 63,000 square foot tilt-up project in Southwest Florida, replacing all steel reinforcement (except stirrups) with BASTECH. Here’s a look at the project:

Project Overview

- 63,000 square foot office facility

- 75 panels – average size 20’ x 24‘

- Originally designed using standard steel rebar

- Basalt Engineering provided revised calculations and details using BASTECH BFRP

Project Results

- No learning curve for in the field employees

- Reduced rebar installation costs by 50% for first-time user

- Completed rebar installation in half the time with half the workers

- Lighter tilt-up panels resulted in faster crane placement

- Project used under 25 tons of BASTECH rebar versus over 75 tons of steel rebar